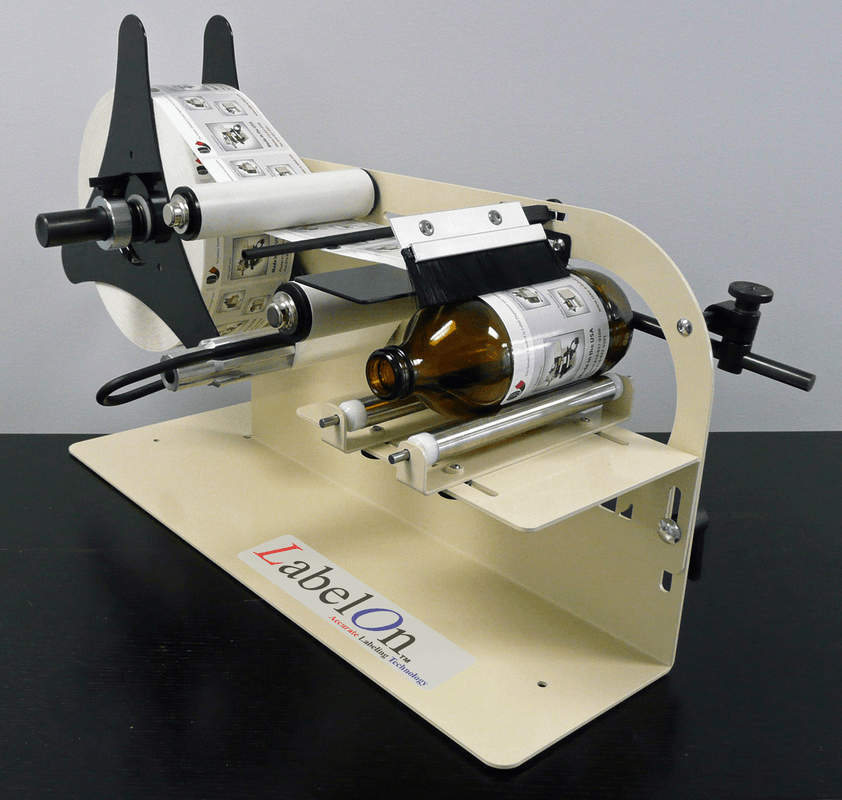

When labelling smaller vials, a BCD (Bottle Capture Device) is a much less “fiddly” set up compared to a Wrap Labeling machine.

Without going into too much of a label thesis; while possible to label small vials with a Wrap Belt it is a more skillful set-up, and you are more reliant on consistent properties of the labels. I agree with Steve that we should return to the recommendation of using the Minis Synergy BCD (Bottle Capture Device).

You can look to get a relatively quiet Air Compressor to compliment it; For example, this unit on Amazon will have enough air capacity for this Mini Synergy BCD. https://www.amazon.com/dp/B01HTONHL8

Note: we have not used it so it’s a suggestion more than a recommendation.

The label thesis if you like:

Wrap Labeling Versus Bottle Capture Device Labeling – Small Diameter Vials

Small vials we have relatively short labels.

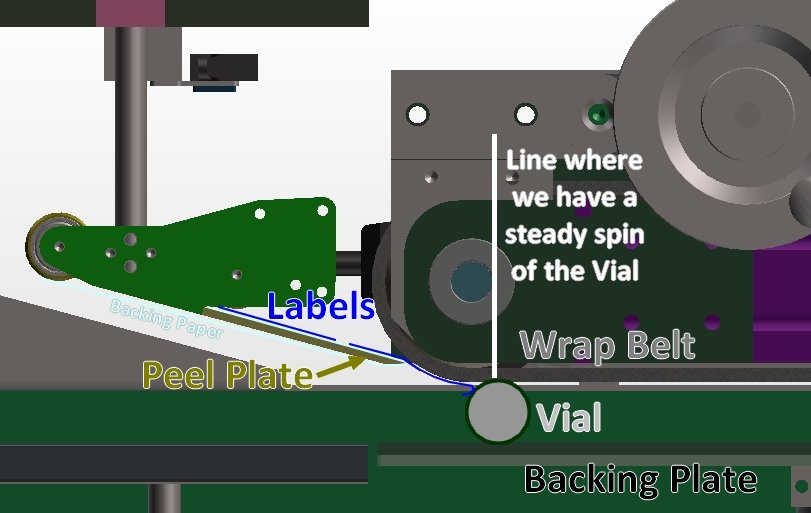

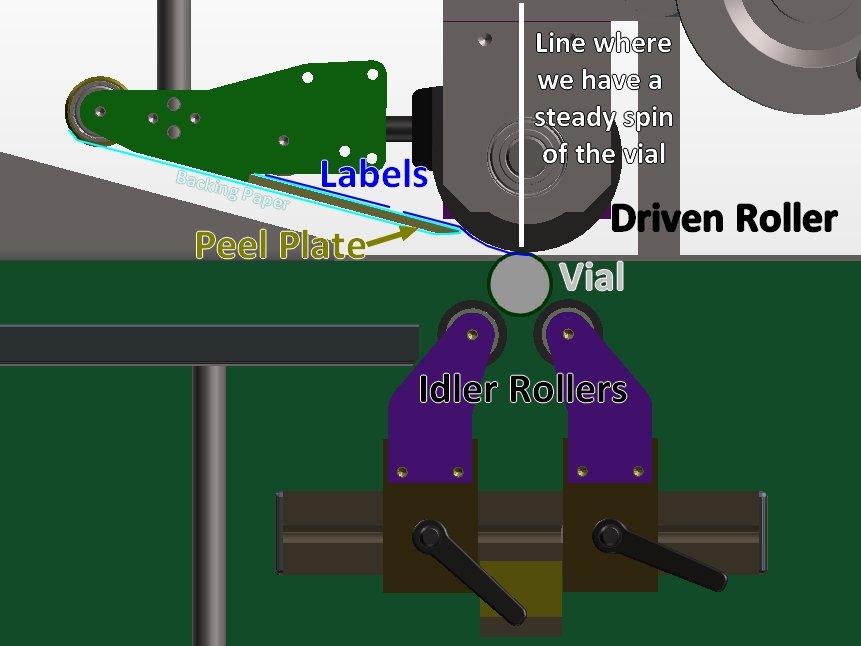

Before the label can be applied to the small vial, the vial needs to enter into a smooth spin between a spinning wrap belt and a stationary (rubberized) backing plate.

The transition from not spinning to spinning takes up some travel distance.

The label feed is twice the speed as the main conveyor speed.

The bottle passes the point where the label is ejected (from the tip of the peel plate) to enter into a spin in the Wrap Belt section.

The label is ejected to “catch up” to the spinning vial and then wrap around the spinning vial.

For small and light weight vials there is usually a little “bump” as the vial enters into the spin section and we need to wait until the vial has passed this “bump point” before the label catches up to the vial otherwise the label will not hit a surface spinning at the same speed as the label feed and this will lead to creases or the label folding back on itself.

The first diagram below shows approximately where we might expect a steady spin passed the “bump point” entry into the Wrap module.

If we try to apply the label before the “bump point” the label can fold back on itself.

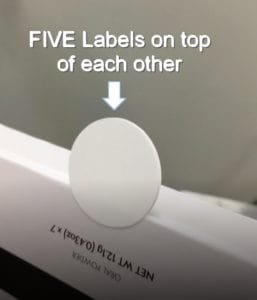

So here is where it can get fiddly to set up a label onto a small vial with a Wrap module; because the label is usually short for a small diameter vial , to avoid the bump point of entry into the wrap module, we will need to have ejected most of the label before the label catches up to the vial’s spinning surface. In this instance, much depends on the properties of the label itself; for example, how stiff the label is and how straight the label peels off its backing paper. In some cases, the label may peel differently when it is a label from the largest outside diameter of a full roll of labels to how it peels as we get close to the smallest outside diameter of a near empty roll of labels. Other Variables that will impact this scenario of small vial Wrap Labeling:

a) Die cut variation; from one roll to another the depth of the die cut of the labels can have a minor effect on how straight the label peels off its backing paper.

b) Vial variations – if the vial has a slight lean variation from its base; which can lead to only partial initial contact with the label as it catches up to the vial leading to creases or the label folding back on itself.

When we use a Bottle Capture Device (BCD) as per the figure below, a steady spin of the vial is achieved closer to the where the label peels from the backing paper.

This method of Labeling makes the Labeling much less susceptible to label and bottle variations.

production.

production.