It is the aim of every product manufacturer to make the best possible product, one that is both exceptional and unique. As such, when you determine what product your business is going to make, you decided to take on the challenge of uniqueness. However, with specific types of products come specific problems. The issues which may arise with the interaction of your top and bottom labeling machine and your product may be distinct and so require innovative solutions.

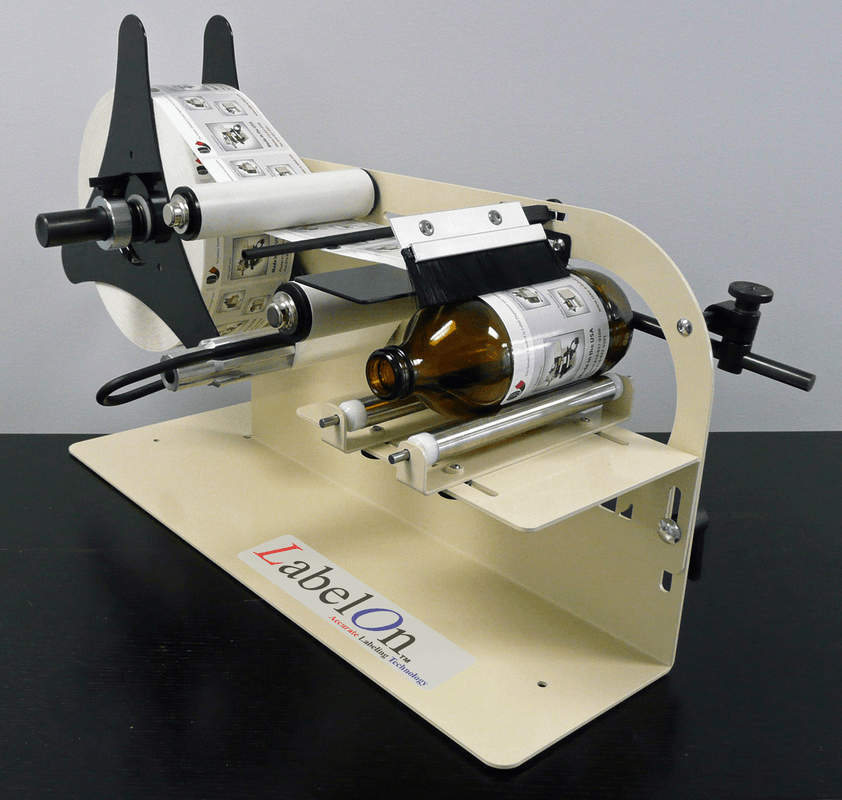

Since your product stands out from the rest, it stands to reason that your labeling requirements may be different as well. Even with the material of the label or shape of your product container, you may find a slew of problems that need to be solved with a fresh mind. So how will you proceed? That’s where our team at LabelOn™ comes in.

Top and Bottom Labeling Machines

First off, evaluating the product at hand is a necessary first step. Since your product is different from others, you may have specific requirements which your top and bottom labeling machine must be well-equipped to handle. Different labeling materials, different information on the labels, different barcodes or designs: all of these must be addressed and dealt with.

Once the specific issues are determined, it is then necessary to find which top and bottom labeling equipment is perfect for you. You will need one that can withstand the rigors of your production without sacrificing speed and accuracy. At LabelOn™, we offer a variety of labeling machine modules, drivers, label heads, and even conveyors to suit your product needs. Our label applicator machines are capable of solving whatever complex problem may arise in your pursuit of providing the best possible product for your own consumers.

Automatic Top and Bottom Labeling Machine Issues and Solutions

We at LabelOn™ pride ourselves in connectivity and communication, no matter where you are on the globe. We are open to a variety of methods—video calls, phone calls, emails—to ensure you get the proper information to solve whatever issues you may encounter with your fully automatic label applicators. We are open to discussing the predicament with you and offering you the best solution to your problems. At LabelOn™, our client’s success is our success.

With the varying regulations for goods retailed within different regions of the world, importers often face the challenge of re or over products. Alternatively, the importer will face the high costs of low volume custom artwork supply pricing from their overseas suppliers.

Our Client

A major video games distributor approached us with the task of applying small labels onto video game covers. That company needed to comply with unique game rating requirements and barcode requirements. In order to comply there needed to be up to four different labels placed onto their imported products.

Importer Top and Bottom Labeling System Requirements Solved

The label applicators had to apply small labels more consistently than their manual operations and help reduce the labor costs involved while speeding up the throughput. Labeling machine accuracy was important and ease of machine set-up was paramount.

The proposal given involved a magazine feed operation where video games were loaded into a chute and fed onto a machine conveyor. From there, the video games would be labeled from the top, the bottom, and from the side (along a spine).

As the placement of labels by the labeling machine would involve small labels covering existing sections of the artwork, product control and label feed accuracy were very important.

Remote Customer Support/Service

Working with phone calls, emails, Skype sessions, CAD drawings, example videos, and samples the project was finalized; without face-to-face meetings. LabelOn™ design and electronic records make project evaluation via modern communication a reality. It does not matter if you are next door or across the world, a LabelOn™ label applicator configuration is easily tailored with real details. We do not need to use slick salesmen; if we get to deal with the Manager or an Engineer then we are confident our labeling machine discussions and proposal will enable a confident and best value proposition decision for your company.

Ahead of receiving their machines, The Video Games client worked with a “cloud” directory containing all the paperwork, machine pictures and operating video, comprehensive spare parts listing – even shipping details. This communications protocol has now evolved to our proprietary Client Gallery System

Top and Bottom Labeler Machine

Importer label applicators are often provided as a top and bottom configuration because the imported items are often boxed. Importers of goods in boxes may need to over label Cereals, Biscuits, Pharmaceuticals, or Cosmetics. These importers can all benefit by using self-adhesive labeling machines and obtaining volume pricing from overseas distributors.

Benefits of the LabelOn™ Automatic Labeling Machines

Should you install LabelOn™ automatic labeling machines, there will be a number of benefits that should become self-evident within days.

- Every Physical Module adjustment and even the Rail adjustments have a rule or scale for recording.

- Large Hand-wheels on Modules to make adjustments easily and accurately

- Label Heads Driven with Five phase (not two phase) Stepping Motors; resulting in smoother and higher resolution label movements – making it possible to start and stop the labels more accurately

- Label Heads often fitted with Spring Loaded Wipers; resulting in even label wipe down pressure

- Label Heads fitted with roll diameter capacity of 380mm (Compared to 320mm of most others) – If you were considering say a 90mm Dairy labels this would increase the number of labels from about 5500 per roll to 8300 per roll

- Overhead Conveyor fitted with a Servo Motor; resulting in a smoother, quieter and cooler operation

- Overhead Conveyor fitted with independently moving spring feet behind the belt; reducing the “bridging problem” where normal bottle variation can lead to two taller bottles either side of a shorter bottle having reduced or no hold down pressure during label application and wipe down

- Main Conveyor fitted with a variable speed A/C motor providing high resolution encoder position and speed feedback; resulting in smoother, quieter and cooler operation and – making it possible to initiate a label feed with more timing/position

- Controls Mounted on a swivel arm; making it possible to adjust machine settings from both sides of the machine

- Touch Panel Controls with memory to hold 120 Jobs

- Machine Status Light Tower; Enabling a quick glance from a distance to gauge what mode the machine is in

- Standard PLC and Motor Drivers – making spare parts an assured thing and preventing the “charge what you want” approach from machine suppliers with custom control boards and motor drivers

- Plugs for all electronics and internal wiring clearly labelled, laid out and easily accessible; making service and repair fast and easy.

- 3-D mechanical model records enabling live internet connection discussions to quickly and visually drill down to any part on the machine – for service, adjustment and replacement discussions (requires a Skype account)

But you may argue that some people find a lopsided label quite charming and homey. However cute as it may seem, it certainly doesn’t scream future-professional-big-business, now does it? And how many products are you willing to label by hand? Although a business may start out with hand labeling their products, as the company grows, having this crucial part of the process automated or even semi-automated, is the natural next step, not only to help ease your burden as the manufacturer but also to maintain that accuracy that you most certainly want to have in your production.

But you may argue that some people find a lopsided label quite charming and homey. However cute as it may seem, it certainly doesn’t scream future-professional-big-business, now does it? And how many products are you willing to label by hand? Although a business may start out with hand labeling their products, as the company grows, having this crucial part of the process automated or even semi-automated, is the natural next step, not only to help ease your burden as the manufacturer but also to maintain that accuracy that you most certainly want to have in your production.

The US Federal government now has an established way to label cannabis for medical and adult use. Once these

The US Federal government now has an established way to label cannabis for medical and adult use. Once these