Brewing Beer as a Business

Amidst all the technical aspects, the licenses, and the requirements needed, once one has perfected that oh so glorious signature taste that will put their brewery on the map, the next thing one will need is the packaging. Beer bottle or beer can? Glass or aluminum? Whichever you choose, bland branding is never a good thing. And that’s where beer labeling comes in.

Any person who has ever owned this type of business has, at one time or another, thought of labeling their product, not just to save up on costs, but also to fully customize their merchandise. With the intricacies related to different types of beer bottle labeling equipment, it is no wonder that many find switching from manual labeling to machine labeling is a daunting task. However, with proper knowledge and guidance, having your beer labeling machine up and running can make for a satisfying experience in your brewery.

How Important is Beer Labeling?

The importance of a good first impression is never lost in interpersonal connections but the same also applies to our products. The brewer’s craft entails meticulous attention to detail but the container in which one presents this beloved product also delivers a lasting impact on the consumer. Along with the taste, the quality, the wording, the packaging—everything is scrutinized by the observant consumer, so why not build upon this and make sure to dole out the charm that only the finest breweries can offer?

For craft beer connoisseurs and those looking for unique pieces to partake in or even to gift to others, a beautifully placed beer label may be just the difference between customers choosing your beer over your competitors’. Commercial breweries with their massive batches churn out an impressive production and it is no secret that their labels gather impressive results. But rarely are these beers considered “memorable.” In peoples’ hearts, a product that is unique and impressive will always be more memorable than mass-produced goods.

Why Invest in Beer Labeling Equipment?

- Pre-Printed Cans or Bottles are an inventory and storage challenge

- Label application is not easily done by hand and can take an arduous amount of time without some level of automation.

- The placement of the label must be accurate and neat as it adds to the finesse of your brand.

- It allows for the consistent positioning of your label.

Before purchasing your beer labeling machine, there are a few factors you need to think of including price, the speed of production, size of the beer bottle/can, and the efficiency of your label applicator.

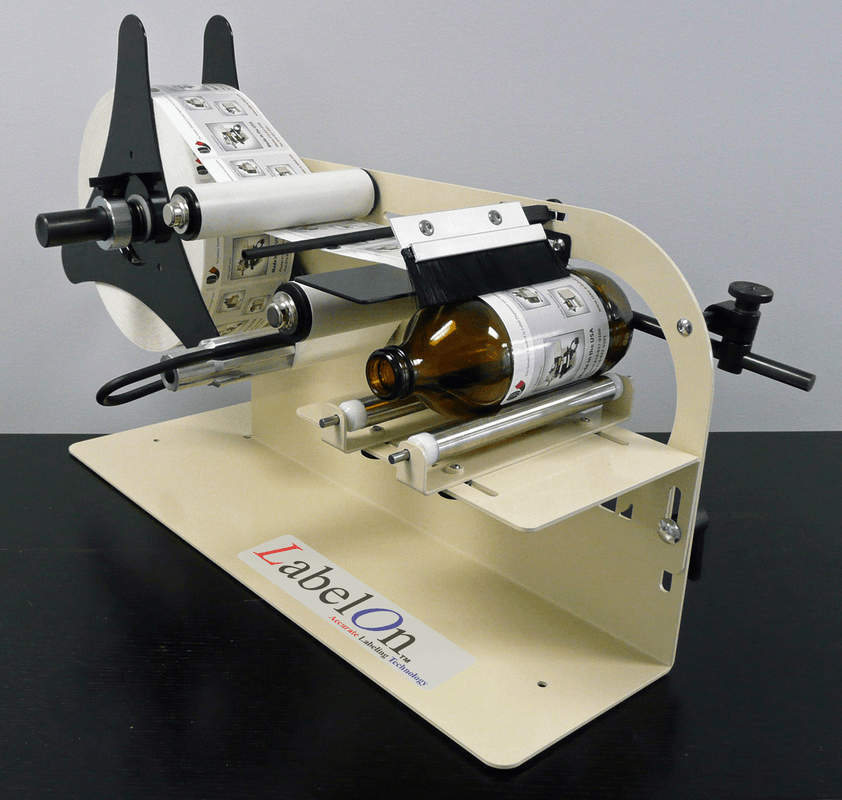

Here we showcase our LabelOn™ Manual Benchtop Round Product Labeler. This setup will let you do away with the tedium of manual label placement and alignment, and improve efficiency in your production line.

This beer can and bottle labeling machine are perfect for round bottles, jars, and cans—either glass or plastic. It has three rollers to guarantee topnotch alignment both on the leading and trailing edges of your labels. Perfect for when your production line includes labeling more than a hundred items per day!

There is also a nifty pointer/reference bar that sits over the label path letting you know when the label has been dispensed and when to stop using the hand crank. This impressive mechanism is also useful for applying two labels from the same roll—front then back. The addition of another pointer allows you to apply your first label, rotate the item, and proceed with adding your second label.

Large Breweries

Beer boutiques and larger breweries can benefit from our Mini BCD Series and Basic BCD series. BCD stands for Bottle Capture Device.

The LabelOn™ Mini Synergy 500 – BCD, captures the product a fraction of an inch away from where the label is ejected from the label head. The product is captured between two vertical and parallel Idler Rollers and a Driven Rubber Roller. This method reduces significantly the possible tilt in the product as it is being labeled and reduces any variations due to the variations in the product’s base “squareness” to its side. The bottle remains captured and spinning while the label is fully released at a Synchronized speed onto the bottle’s spinning surface. Typically, the label alignment of the leading and trailing ends will vary approximately +/- 0.5mm up and down.