Plastic or Glass

As the world is becoming more environmentally conscious and awareness of the detriments of plastics has grown, there has been a shift to the use of glass bottles in the name of sustainability. The potential issues that arise from plastic use, however, do not take away from the fact that plastic products and packaging are still incredibly versatile and important. Both glass and plastic are still used to package a variety of products and the material and method by which these products are packaged lead to a big difference in glass bottle labeling versus plastic ones.

This begins with the components these two are made from. Plastic products can be made of polymers from polyethylene terephthalate (PET), high- and low-density polyethylene, polystyrene, and others. Plastic packaging can form barriers against moisture and are very versatile in their applications. Glass bottles, on the other hand, are made from natural materials like silica sand, limestone, soda ash, and material from recycled glass, called “cullet.” These confer sturdiness and inertness to glass bottles, making them reusable and less problematic for the consumers’ health.

Both products have multiple applications in various fields. With packaging, plastics don’t break like glass bottles when dropped. They are also more forgiving in their flexibility and are easier to configure into many shapes and sizes. Glass bottles for their part, are more heat-tolerant and do not warp under high temperatures. They are also more impermeable than plastic, allowing them to hold more corrosive substances than plastic can.

Here are some of the aspects that differ when labeling glass bottles versus plastic ones.

Labeling Plastic Bottles or Glass Bottle

1. Product Handling

With glass bottle labeling, you need to be more careful with product handling as glass breaks. Extra precautions include ensuring there are no places where a build-up of the product would result in an overflow of product that would fall off the machine. Glass bottles can “catch” on one another and cause jams. Pinch points can shatter glass where plastic bottles will simply crumple. Some product handling can result in jams under just the wrong conditions because the glass jar will not budge in shape.

2. Labeling Surface Consistency

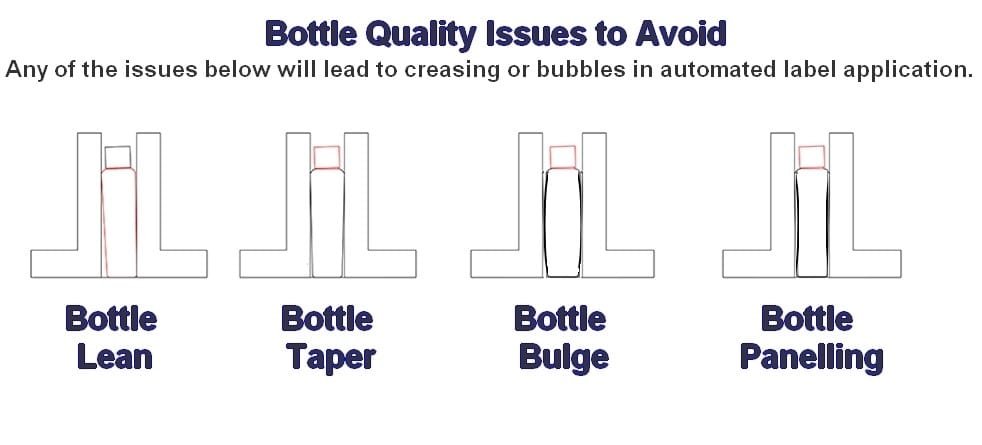

Plastic jars and Glass products can have crappy labeling surfaces or inconsistent shapes and labeling surfaces.

When dealing with round glass jars, we have found higher pressure of application along with softer application rollers produces better results where there are undulations on the surface.

With Plastic bottles, you don’t have the luxury of applying more pressure as the bottle will deform.

In both plastic and glass bottle labeling, the best solution is to change supply and find good quality packaging where there are no labeling surface undulations.

3. Adhesives and the Surface

Adhesives will perform differently with both Glass bottles and Plastic bottles.

With clear labels, there is a term called adhesive wet-out where small microbubbles, visible just after application, simply “go away”.

It’s a good idea to check with your label stock supplier if the adhesive on your labels is well matched to glass or plastic depending on the products you are labeling.

4. Shape Changing

In some cases, plastic containers will change shape or panel with different temperatures or with certain contents where gases are either produced or consumed within a sealed container. On a labeled container this can lead to creases or bubbles appearing after what looks like a smooth label application. A glass bottle is very unlikely to have these types of issues.

5. Static Electricity

Plastic containers, compared to glass, are more likely to build up static electricity and this can affect label application and lead to bubbles or creases.

6. Outgassing

In some cases, plastic can give off gas or even let gasses pass through its walls. This can create bubbles on what looks like a previously well-labeled product.

In most cases, if we have a representative sample of products to examine, and a short video of the current labeling process, we will be able to identify where the source of problem bubbles or creases is coming from.

Plastic and glass bottles have their own sets of pros and cons and different applicabilities depending on the product you want to package. Their differences mean that both the labels on glass bottles and their plastic counterparts, as well as the general labeling process will differ for the two of them.

If you have questions regarding glass bottle labeling, feel free to drop us a message by chatting with our representatives. Alternatively, get a quick quote by filling up our two-part web form. It will only take less than two minutes of your time.