Upgrading your production from a manual or semi-automatic to a fully automatic labeling setup can be quite expensive for emerging companies with a tighter budget. It may not be feasible to buy the bigger and shinier models just yet. With this in mind, we introduce you to LabelOn™ ‘s Basic Round Bottle Labeling Machine.

Our automatic round bottle labeling machine has all the requirements you need and then some. There are three models you can choose from, depending on the type of wrap labeling you require as well as the number of labels you would like to apply to your products. The machines have high-resolution Five Phase Stepper Motors to allow for a perfect and accurate label application each time. They even have automatic setting label gap sensors so you won’t need to worry about misaligned labels.

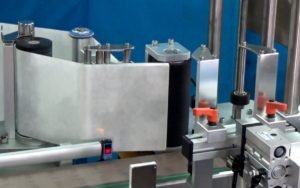

LabelOn™ Basic Labeler Machine Range

A key feature of the lineup is ensuring repeatability of your labeling, as you can set programs for each product you need to be labeled. Once you input the proper configurations onto the computer, you can save the program for that specific product, saving you valuable time because you no longer need to change the settings each time. This boosts production efficiency even more.

LabelOn™s Basic lineup also works well with our modular lineup so you can upgrade once your business needs it without drastically altering your current setup. This means that these automatic round bottle labeling machines will allow for setup expansion and growth with you as your company flourishes. And because it is closely related to our modular setups, you can include other optional parts to your machine as well, making production run even more smoothly.

With the LabelOn™ Basic Round Product Labeling Machines, you are given the chance to dip a toe into an automated labeling production line without splurging right away. It is a new technology that can grow with you and help you achieve what you need to grow your business.

LabelOn™ Basic is the range of equipment we offer clients on a tight budget with more basic requirements. You get what you pay for, only with the LabelOn™ Basic Range. You also have the benefit of equipment closely related to the LabelOn™ Modular range – an unparalleled bottle labeling machine range in its class of in-line labellers. With this LabelOn™ Basic range, you can get a very clear picture of what measures are taken to achieve a more basic and more budget-friendly labeler machine that will fit the requirements of those under budget pressure to get a job done as efficiently as possible.

Basic Labeling Machines for Round Bottle Labeling

The LabelOn™ Basic range includes three models that can label Round Cylindrical products:

LabelOn™ Basic 500 – Wrap up to 85% Wrap labels.

LabelOn™ Basic 500 – VW up to 95% Wrap labels with the option to label 1 or 2 Labels.

LabelOn™ Basic 500 – BCD up to 100% Wrap labels with the option to label 1 or 2 Labels and the additional option to label with orientation

- Repeatability – All Electronic settings/parameters of your production job can be saved on the touch screen allowing exact repeatability between runs.

- Touch Screen Controls – has easy-to-use and easy-to-understand su_buttons. There is also machine status information and troubleshooting menus.

- Five Phase Stepper Motors – The label heads are fitted with high resolution Five Phase stepper motors enabling for smooth and very accurate label feeding.

- Auto Setting Label Gap Sensor – The Sensor will pick up on different types of baking paper and adjust the label gap sensor automatically.

- Label minimum thickness – 70micron

- Label reel core size 76mm inside diameter

- Label reel outside diameter 380mm (std)

- Label minimum size – Vertical 15mm/Horizontal 15mm

- Label web maximum height –155mm (selected at the time of order)

- Label gap minimum size – 2.5mm

- Speed Synchronised to Label Feed

- Dispensing speed minimum – 5m/min (Standard)

- Dispensing speed maximum – 30m/min (Standard)

- Label accuracy ± 1.00mm – not including variations due to the Bottles or Labels

- Stepper motor drive – 5 Phase – Note older machine designs use a 2 Phase Motor that is more Coarse and Hot in operation

- Missing label detection (Standard)

- Low-level roll detection (Standard)

- Un-locked Drive Roller Assembly alarm (Standard)

- Clear label gap sensor (optional)

- Conveyor speed 5 – 30 m/min (Standard)

- Conveyor Height 820mm – 870 mm (Standard)

- Conveyor Length 2000 mm (Standard)

- Conveyor material – Plastic Slat/Stainless Slat/ PU Belt/Rollers

- Conveyor widths – 105mm (Standard)

- Conveyor Non-Stalling Motor Drive with Continuous Speed Feedback (Standard)

- Bottle Separator

- Wrap module (85% wrap or less) or

- Vacuum Wrap (95% Wrap or less; 1 or 2 labels) or

- Bottle Capture Device (100% Wrap or less; 1 or 2 Labels, Orientation Labeling optional)

- Label Counter

- Batch Counter

- 120 Jobs Memory

- Missing Label Alarm

- End of Label Roll Alarm

- Unlocked Drive Roller Alarm

- Overhead conveyor – Servo Motor Driven

- Coder – thermal or inkjet

- Aligner Spacer (Oval Bottles)

- Side grip twin belt transfer system