Self Adhesive Labeling

Clients of LabelOn™ Modular Self Adhesive Labeling Machines are realizing that with the uncertainty of machine set-up removed they can concentrate on other variables that influence machine results.

One area that is often overlooked is the consistency of bottles. In this article, we concentrate on complex contours. This is where the bottle or product has a curved surface in more than one direction. The label applicator can control the movement of the products and its labels to be applied but it cannot control the shape of the products or label.

Testing for Complex Contours

The first step is to identify the area of the product where the label is expected to be placed. Then, using a business card, hold the edge of your business card vertically against the product. Move the edge over the entire area where the label is expected to be applied. If a gap appears between the edge of the business card and the bottle surface then you have at least one curve, in this case in the vertical direction, on the area to be labeled.

Note: A curve in the vertical direction is usually a problem for self-adhesive labels as it is a curve that is difficult for a label to follow as it is usually dispensed in a direction horizontal to the product; matching the way the bottle product/bottle travels on a product conveyor.

While a flat label can “wrap” in the direction of one curve on a product’s surface, it cannot wrap in more than one direction. Taking the business card used before, and holding it horizontally against the surface you now look for gaps between the card’s edge and the product surface in the same area you found gaps when the card was vertically orientated.

Note: Curves in a Horizontal direction alone are quote common – round bottles being an obvious case but also oval cross-section bottles such as shampoo bottles or detergent bottles.

If you do find a business card that can show gaps in both a Horizontal and vertical orientation then that area of the bottle cannot be labeled with a self-adhesive label without bubbles or creases.

Learning from the Mistakes of Others

To see some examples of complex contour mistakes, you can visit a supermarket and look for products labeled with creases or bubbles. Most of the time it will be because of a mistake in the bottle/label design where the label is expected to go over a complex contour.

Another test to convince yourself of the problem of over-complex contours is to take a sheet of paper and see what happens when you try to wrap the sheet of paper onto a ball. You will always get creases for the paper to be pressed against the ball.

For Round bottles and products, there is a very quick check to see if complex contours exist. Take two round products and put them beside one another with their edges touching. See if you can see any gap between the touching edges.[/su_column][column size=”1-2″ last=”1″ style=”1″]

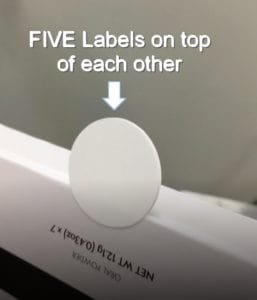

Now rotate the bottles while they still touch and see if you see gaps appear and disappear. Gaps suggest complex contours and the likelihood of creasing in these areas if labeled. In this case, the complex contours are not designed but more a result of the bottle quality and variations.

Other sources of complex contours for label applicators can be very thin-walled flat-sided bottles. Here the thin walls of the bottles can lead to surface irregularities before and after filling. Depending on where the label applicator is placed it can be a good idea to label thin wall bottles while they are empty; especially if they are hot-filled.

production.

production. “it’s not working anymore”

“it’s not working anymore”