Start the conversation that suits your needs

Every labeling line and packaging setup is unique. Here, we invite you to select a session that best fits your current situation — whether it’s a quick check-in, detailed technical support, or a strategic consultation. We approach every interaction with curiosity and care, helping you understand options before making decisions.

Quick Technical Support

LabelOn™ – Free Out of Warranty Service / Inspection

10-Minute Remote Video Call

Free

- Ideal for a fast, no-pressure check-in

- Perfect for minor questions or initial troubleshooting

- Free and designed to help you clarify next steps

This service is available to direct clients of Adeneli; if you just purchased a second hand machine or through another indirect path please select:

LabelOn™ One Hour Block Video Call (US$120)

For Direct clients of Adeneli this LabelOn™ Free out of warranty 10 Minute remote Video call service/inspection is your first port of call to see if your out of warranty issue can be resolved with a quick call.

While the staff that may be available to take these calls at short notice may not be experienced engineers they can assist in your collecting the relevant information and some known common quick fix issues.

Preparing for Your Maintenance or Service Session

To help streamline maintenance and service calls, we strongly recommend documenting any issues or questions before your session by uploading narrated videos and photos to your Client Gallery. This allows our technicians to review the situation in advance and ensures your session time is used as effectively as possible.

Maintaining a history of past issues in your gallery also helps make future sessions more efficient and, in some cases, may eliminate the need for a service call altogether.

If you do not have access to your Client Gallery or have misplaced your login details, please email steve@adeneli.com for assistance.

How to Document Issues Using Videos and Photos

When recording a new issue or question, please follow the guidelines below:

Record narrated video(s)

Provide one or more videos of at least 30 seconds each.

Begin with a clear, overall view of the machine.

Slowly pan to the specific area of concern while explaining what you are seeing and experiencing.

Explain recent changes

If applicable, describe any recent changes, adjustments, or configuration updates made around the time the issue first appeared.

Clear narration and visuals significantly improve our ability to diagnose and resolve issues efficiently.

Uploading to Your Client Gallery

Inside your Client Gallery, you will find an Upload link located in the top-left corner of the screen. Use this link to upload all related videos and photos for the issue you wish to review.

Alternatively, you can also use the QR code Below to upload your pictures and Video to our generic Service calls Gallery.

Or you can send this link to a mobile phone so that the phone can upload the media:

https://adenelipackaging.com/v/servicegalleryupload

Spare Parts and Service Efficiency

Having recommended spare parts available can significantly improve the efficiency and effectiveness of a booked service session. Spare parts are often used to temporarily replace a suspected component, allowing us to confirm whether that item is the cause of the issue. This swap-out process helps narrow down possible causes and trace the problem to its actual source.

Without spare parts on hand, troubleshooting may require multiple sessions and can take days or even weeks while parts are identified, ordered, and delivered. By contrast, having suitable spare parts available can allow issues to be isolated and, in many cases, resolved during the same service session—helping you return to operation much faster.

If you wish, we can email you a list of recommended spare parts for your specific machine so they can be purchased prior to booking a service appointment.

Service Scope and Expectations

While our goal is always to be as effective as possible, there is no guarantee that all issues can be identified or resolved within this 10 minute session.

Further Service sessions are provided on a time-based basis at $120 per hour or part thereof. During this time, our technician can:

Assist with troubleshooting and setup-related issues

Make recommendations for adjustments or parts that may be required

Use spare parts (where available) to help isolate suspected causes

Collect relevant information to determine appropriate next steps

If required, we can also gather technical details and discuss follow-up actions that may involve consultation with other engineers or our partner manufacturers.

To make best use of your session time—particularly for setup or configuration-related matters—we recommend carefully documenting any changes you have already made. This allows us to continue from where you left off and avoids spending time revisiting steps you have already covered.

Preventative Maintenance & Ongoing Training (Strongly Recommended)

We strongly recommend scheduling this service for at least one hour every six months as a Preventative Maintenance Inspection and/or to support training for new or existing staff.

Preventative maintenance is far more effective than reactive repair. Much like maintaining personal health, proactive care of your equipment helps identify potential issues before they lead to downtime.

During these sessions, we can often:

Identify parts that may require attention or replacement

Correct settings that affect performance, reliability, or machine longevity

Improve operator understanding and confidence

Reduce the likelihood of unplanned outages

Regular preventative maintenance and training help protect your investment and ensure your equipment continues to operate at its best.

Senior Engineer Guidance

LabelOn™ – Senior Engineer

One-Hour Block Video Call

US$240 – Best for Older Machines

- For older or second-hand LabelOn™ machines

- Deep technical review by a senior engineer

- Guidance on repairs, upgrades, or operational issues

LabelOn™ - Senior Engineer - One Hour Block Video Call (US$240 - Best for Older Machines)

Training, Maintenance, or Out-of-Warranty Service – Second-Hand Machine

For older equipment, this premium service provides access to our Senior Engineers—experts who were directly involved in the design, specification, and pre-delivery testing of these machines. Their deep understanding of the original engineering and operational requirements ensures the most informed guidance and support for keeping legacy equipment running effectively.

Note :You may want to book consecutive blocks where you feel more than one hour is appropriate.

To streamline Training, Preventative Maintenance and Service calls it is always a good idea to document any problems or questions with videos (Narrated) and pictures which you have uploaded to your client Gallery (see instructions below).

If you do not have or have lost your access to your client gallery please email steve@adeneli.com for assistance.

Note, having a record of past issues in your gallery will make any subsequent calls more effective and can even avoid calls altogether.

Instructions on Uploading Videos to Our Online Gallery

1. When documenting a new query or issue, one or more videos of at least 30 seconds with you narrating. It is best if the video(s) start with an overall view of the machine then they pan to the area (in question) with your narration.

2. If applicable , Describe any recent changes or adjustments made around the time issue you wish to go over started presenting itself.

You can also use the QR code Below to upload your pictures and Video to our generic Service calls Gallery.

Or you can send this link to a mobile phone so that the phone can upload the media:

https://adenelipackaging.com/v/servicegalleryupload

Spare Parts

Note , having spare parts on hand can significantly increase the efficiency of a booked service related call. With spare parts on hand the possible causes of issues can be quickly narrowed down and often quickly resolved. You can request a list of recommended spare parts for your machine to be emailed to you for purchase prior to moving onto booking a service appointment.

Just to help set the expectations.

There is no guarantee we can solve or cover all the issues you wish to cover in one hour; especially on older machines purchased second hand.

We can assist on a nominally paid basis of $240 per hour to see if we can make suggestions on adjustments and or parts that may be required to help resolve the issues in question.

We are also able to collect information and discuss what to do next should we need the input of our machine manufacturers or other Engineers.

With service and set up related issues, it is a good idea to document carefully each change you have made so we can take off from where you have left off and not spend too much time covering ground you have already covered.

It is a good idea to schedule this service ongoing at least one hour every 6 months as a Preventative Maintenance Inspection on older equipment and or to help train new staff.

Prevention is far better than the cure with this equipment.

Just as we are learning it is our responsibility to take care of our own health before we get sick a similar responsibility should be considered for looking after the upkeep of your equipment.

Often we can spot parts that need attention or replacement and we can spot settings that, with correcting, will enhance machine longevity and/or performance.

Service & Maintenance Calls

LabelOn™ – Service Call

One-Hour Block

US$120 or Warranty

- Routine maintenance or repair sessions

- Covers machines still under warranty

- Focus on keeping your labeling line running efficiently

LabelOn™ - Service Call - One Hour Block (US$120 or Warranty)

Maintenance or Service (Within Warranty Period)

Note :You may want to book consecutive blocks where you feel more than one hour is appropriate.

Warranty Booking Information

This service is also available for machines that are currently under warranty.

When a booking is made using a Warranty Code, the session will proceed as scheduled. If, during the session, it is identified that the issue relates to setup or configuration, operator error, power or air supply utilities, or general unfamiliarity with the machine—and not a fault with the equipment itself—the session will be billed at our standard service rate of $120 per hour or part thereof.

To help minimise these situations and ensure optimal performance of your equipment, we also offer structured training sessions for operators and maintenance staff. These sessions are designed to improve understanding, efficiency, and reliability, and we recommend scheduling training at least once every six months.

Preparing for Your Maintenance or Service Session

To help streamline maintenance and service calls, we strongly recommend documenting any issues or questions before your session by uploading narrated videos and photos to your Client Gallery. This allows our technicians to review the situation in advance and ensures your session time is used as effectively as possible.

Maintaining a history of past issues in your gallery also helps make future sessions more efficient and, in some cases, may eliminate the need for a service call altogether.

If you do not have access to your Client Gallery or have misplaced your login details, please email steve@adeneli.com for assistance.

How to Document Issues Using Videos and Photos

When recording a new issue or question, please follow the guidelines below:

Record narrated video(s)

Provide one or more videos of at least 30 seconds each.

Begin with a clear, overall view of the machine.

Slowly pan to the specific area of concern while explaining what you are seeing and experiencing.

Explain recent changes

If applicable, describe any recent changes, adjustments, or configuration updates made around the time the issue first appeared.

Clear narration and visuals significantly improve our ability to diagnose and resolve issues efficiently.

Uploading to Your Client Gallery

Inside your Client Gallery, you will find an Upload link located in the top-left corner of the screen. Use this link to upload all related videos and photos for the issue you wish to review.

Alternatively, you can also use the QR code Below to upload your pictures and Video to our generic Service calls Gallery.

Or you can send this link to a mobile phone so that the phone can upload the media:

https://adenelipackaging.com/v/servicegalleryupload

Spare Parts and Service Efficiency

Having recommended spare parts available can significantly improve the efficiency and effectiveness of a booked service session. Spare parts are often used to temporarily replace a suspected component, allowing us to confirm whether that item is the cause of the issue. This swap-out process helps narrow down possible causes and trace the problem to its actual source.

Without spare parts on hand, troubleshooting may require multiple sessions and can take days or even weeks while parts are identified, ordered, and delivered. By contrast, having suitable spare parts available can allow issues to be isolated and, in many cases, resolved during the same service session—helping you return to operation much faster.

If you wish, we can email you a list of recommended spare parts for your specific machine so they can be purchased prior to booking a service appointment.

Service Scope and Expectations

While our goal is always to be as effective as possible, there is no guarantee that all issues can be identified or resolved within a one-hour session.

Non Warranty Service sessions are provided on a time-based basis at $120 per hour or part thereof. During this time, our technician can:

Assist with troubleshooting and setup-related issues

Make recommendations for adjustments or parts that may be required

Use spare parts (where available) to help isolate suspected causes

Collect relevant information to determine appropriate next steps

If required, we can also gather technical details and discuss follow-up actions that may involve consultation with other engineers or our partner manufacturers.

To make best use of your session time—particularly for setup or configuration-related matters—we recommend carefully documenting any changes you have already made. This allows us to continue from where you left off and avoids spending time revisiting steps you have already covered.

Preventative Maintenance & Ongoing Training (Strongly Recommended)

We strongly recommend scheduling this service for at least one hour every six months as a Preventative Maintenance Inspection and/or to support training for new or existing staff.

Preventative maintenance is far more effective than reactive repair. Much like maintaining personal health, proactive care of your equipment helps identify potential issues before they lead to downtime.

During these sessions, we can often:

Identify parts that may require attention or replacement

Correct settings that affect performance, reliability, or machine longevity

Improve operator understanding and confidence

Reduce the likelihood of unplanned outages

Regular preventative maintenance and training help protect your investment and ensure your equipment continues to operate at its best.

Optimizing Performance

LabelOn™ – Service Call

One-Hour Block – Video Call

US$120

- Training, Maintenance or Service

- This improves business management by shifting machine training, maintenance, and service from reactive urgency to proactive importance.”

LabelOn™ - Optimizing Performance - One Hour Block - Video Call (US$120)

Training, Maintenance or Service

This moves your machine Training, Maintenance or Service out of Quadrant 1: Urgent and Important and into Quadrant 2: Not Urgent but Important

You can prevent the issues before they develop

Note :You may want to book consecutive blocks where you feel more than one hour is appropriate.

To streamline Training, Preventative Maintenance and Service calls it is always a good idea to document any problems or questions with videos (Narrated) and pictures which you have uploaded to your client Gallery (see instructions below).

If you do not have or have lost your access to your client gallery please email steve@adeneli.com for assistance.

Note, having a record of past issues in your gallery will make any subsequent calls more effective and can even avoid calls altogether.

Instructions on Uploading Videos to Your Online Gallery

1. When documenting a new query or issue, one or more videos of at least 30 seconds with you narrating. It is best if the video(s) start with an overall view of the machine then they pan to the area (in question) with your narration.

2. If applicable , Describe any recent changes or adjustments made around the time issue you wish to go over started presenting itself.

Inside your Gallery is an upload link in the top left corner.

You can also use the QR code Below to upload your pictures and Video to our generic Service calls Gallery.

Or you can send this link to a mobile phone so that the phone can upload the media:

https://adenelipackaging.com/v/servicegalleryupload

Spare Parts

Note , having spare parts on hand can significantly increase the efficiency of a booked service related call. With spare parts on hand the possible causes of issues can be quickly narrowed down and often quickly resolved. You can request a list of recommended spare parts for your machine to be emailed to you for purchase prior to moving onto booking a service appointment.

Just to help set the expectations.

There is no guarantee we can solve or cover all the issues you wish to cover in one hour.

We can be there to assist on a nominally paid basis of $120 per hour to see if we can make suggestions on adjustments and or parts that may be required to help resolve the issues in question.

We are also able to collect information and discuss what to do next should we need the input of our machine manufacturers.

With service and set up related issues, it is a good idea to document carefully each change you have made so we can take off from where you have left off and not spend too much time covering ground you have already covered.

It is a good idea to schedule this service at least one hour every 6 months as a Preventative Maintenance Inspection and or to help train new staff.

Prevention is far better than the cure with this equipment.

Just as we are learning it is our responsibility to take care of our own health before we get sick a similar responsibility should be considered for looking after the upkeep of your equipment.

Often we can spot parts that need attention or replacement and we can spot settings that, with correcting, will enhance machine longevity and/or performance.

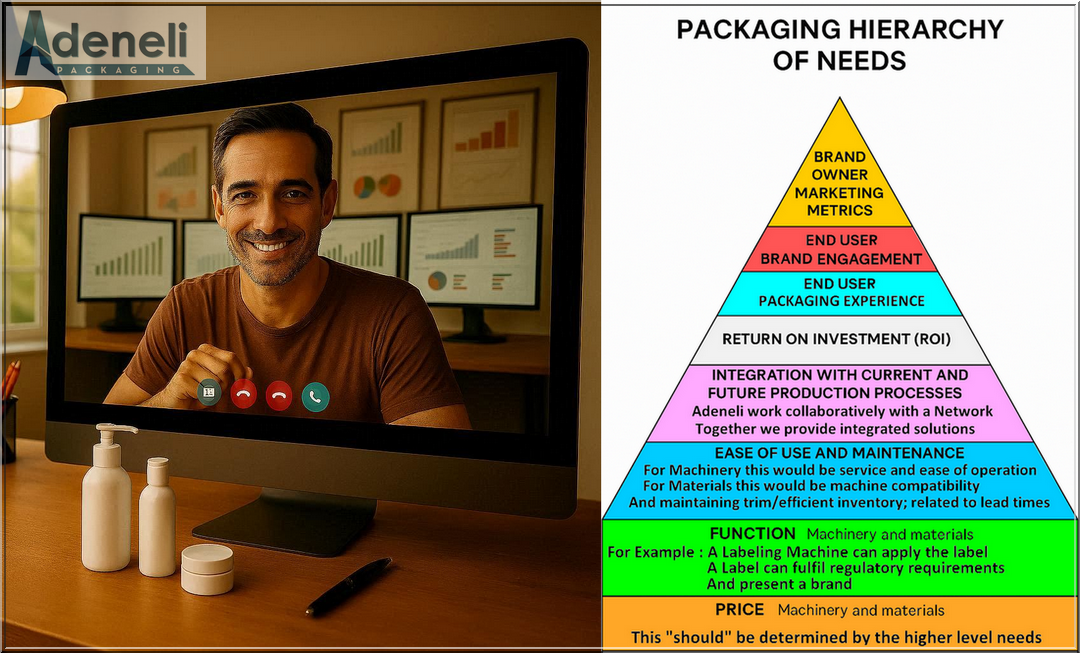

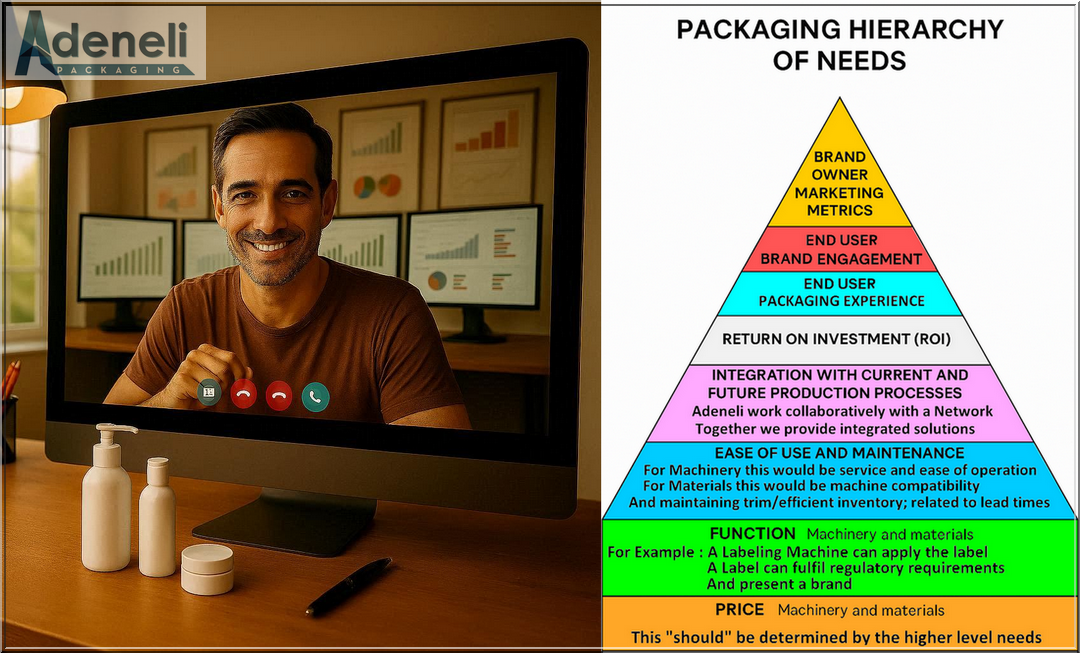

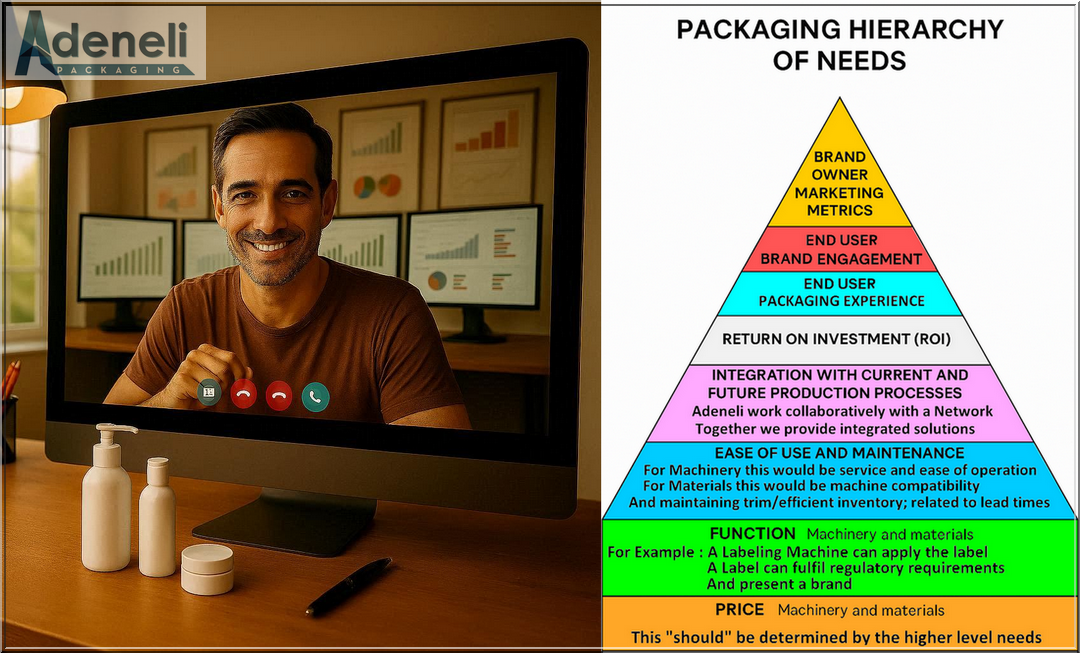

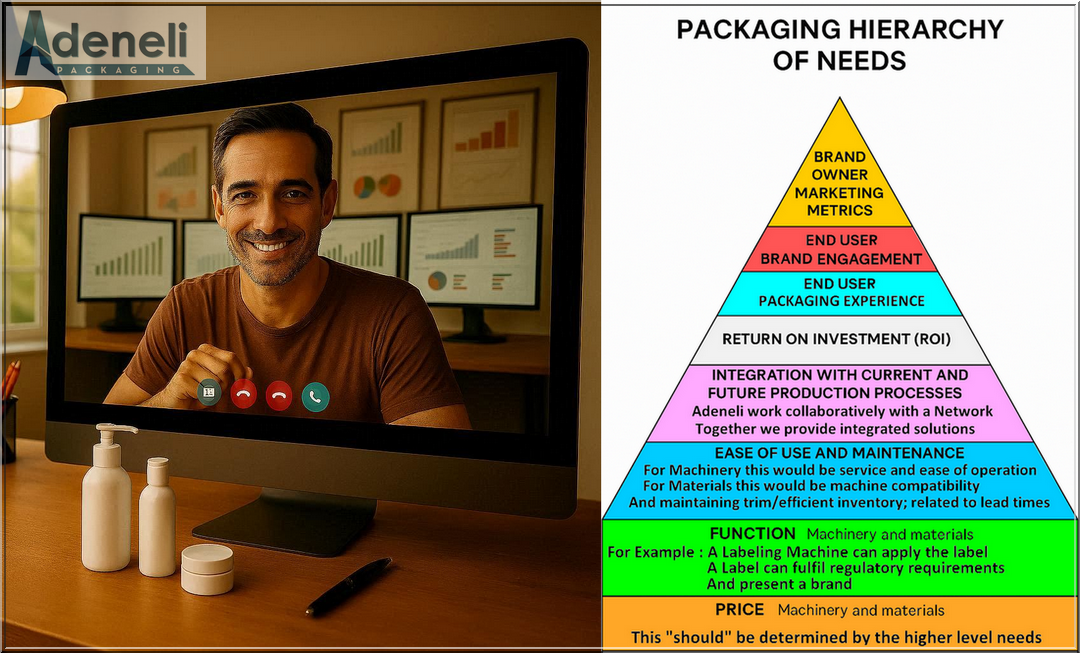

Strategic Packaging Consultation

Packaging Strategy & Consultation

Zoom Meeting – One Hour Block

US$400

- Led by Ben Bornstein, CEO, with over 30 years of experience

- Strategic guidance to improve operational efficiency, cost control, and material performance

- Examines packaging decisions in the context of workflows, consumables, and business outcomes

- Where appropriate, connects clients with industry contacts for next steps

Packaging Strategy & Consultation - Zoom Meeting - One Hour Block (US$400)

With over 30 years of experience in the supply of packaging equipment and materials, our CEO, Ben Bornstein leads the strategic packaging consultations focused on improving operational efficiency, cost control, and material performance. His approach looks beyond isolated packaging decisions to how packaging choices cascade through operations, consumables, workflows, and overall business outcomes. Where appropriate, we can also connect clients with relevant industry contacts to support next steps.

Key Guiding Principle:

A diagnosed problem is more than half solved.

Identified problems represent identified opportunities—serving as the starting point for meaningful improvements in packaging processes, consumable usage, and decision-making across the packaging value chain.

In addition to his packaging expertise, Ben has extensive experience organising and facilitating meetings and discussions with individuals across a wide spectrum of professions. These include company founders, corporate leaders, academics, policymakers, medical and technical professionals, legal experts, media figures, and high-net-worth individuals.

Working at this level has refined Ben’s ability to quickly establish context, ask the right diagnostic questions, and guide focused discussions that help decision-makers clarify priorities, align packaging strategy with operational realities, and concentrate on the opportunities that matter most.

Strategic Packaging Consultation Introduction

Packaging Strategy & Consultation

Zoom Meeting – 10 minutes

Free

- Inquire about Consultation Services

- Strategic guidance to improve operational efficiency, cost control, and material performance

- Examines packaging decisions in the context of workflows, consumables, and business outcomes

- Where appropriate, connects clients with industry contacts for next steps

Packaging Strategy & Consultation Introduction - 10 Minutes

Welcome to smarter, more effective packaging.

Launching a new product? Updating an existing line? Rethinking how to present and protect your items?

We work with you to co-create a tailored packaging strategy shaped by your product, brand, and goals. Together, we clarify the full potential of your packaging—how to select and combine the right materials, sustainability options, compliance requirements, cost efficiencies, timelines, and market fit—to deliver a solution with strategic and practical impact.

New Machine or Consumables Inquiry

LabelOn™ – New Machine and/or Consumables Inquiry Appointment

Free – 20 Minute Call

- Explore new equipment options or consumable needs

- Ideal for early-stage discussions without commitment

- Focused on understanding what may best suit your operation

LabelOn™ - New Machine and/or Consumables Inquiry Appointment - 20 Minutes

This Service is for New Inquiries or New Applications Only

To streamline Inquiry calls it is always a good idea to have to hand:

a) Actual Products That you may need equipment for or actual consumables you may want to source

b) An Idea of the Quantities Involved

In the case of equipment - How Many Units per Minute or Units Per Hour you would like to get through

In the case of Consumables - How many of that consumable per month or per year

c) A Budget Range - a LOT of time can be saved if you can relate the budget range that you would like your solution to fit within.

As a Guide for Labeling Equipment:

d) Other helpful information to have is what other processes you may be looking into as we can also assist with packaging equipment for

Filling, Capping and Induction Sealing.

Ahead of a appointment sharing pictures and Videos can significantly improve the focus and speed with which the best option is identified during the appointment.

Probably the best media you can upload includes pictures of the products you are dealing with and narrated videos that show the product and the area you hope to be producing the product.

You can also use the QR code Below to upload your Pictures and Video to our generic Appointments Gallery.

Or this Link:

https://adenelipackaging.com/v/servicegalleryupload

How to Choose a Session

If you’re unsure which session fits best:

- Start with a quick 10-minute call to clarify your needs

- Move to service, performance, or senior engineer sessions as needed

- Consider a strategic consultation if you want guidance that looks beyond the machine to overall packaging operations

At LabelOn™ and Adeneli Packaging, we believe good support starts with listening. Every session is designed as a collaborative conversation — to help you understand your equipment, optimize your processes, or explore strategic opportunities with confidence.