Thermal transfer printer ribbons are crucial components in the world of label printing, ensuring high-quality and durable prints. This article will explore the types, benefits, and applications of thermal transfer ribbons, helping you make informed decisions for your printing needs.

What Are Thermal Transfer Printer Ribbons?

Thermal transfer printer ribbons are consumable supplies used in thermal transfer printers to print text, images, and barcodes onto various media. The ribbons work by transferring ink from the ribbon to the label material using heat, creating a permanent print that is resistant to smudging and fading.

The ink layer contains pigments or dyes that are melted and transferred onto the printing material when heat is applied. The ink layer is designed to be compatible with the printing material and ensures excellent adhesion, resistance to smudging, and long-term durability of the printed output.

The protective coating, also known as the backcoat, is applied to the underside of the ribbon. It serves multiple purposes, such as reducing static and friction during printing, protecting the print head from wear and damage, and improving the overall performance and lifespan of the ribbon.

The choice of ribbon type depends on the specific application and desired print quality, durability, and resistance requirements.

Thermal transfer printer ribbons come in different types and formulations to suit specific printing needs.

Key Features to Consider

- Print Quality

- Resolution: Higher resolution ribbons produce finer, more detailed prints. Consider your printing needs and select a ribbon that matches your desired print quality.

- Durability

- Resistance: Evaluate the environmental conditions the labels will be exposed to, such as exposure to chemicals, heat, or abrasion, and choose a ribbon that meets these requirements.

- Compatibility

- Media Type: Ensure that the ribbon is compatible with your printer and the media you plan to print on. Different ribbons are optimized for specific types of media.

- Cost-Effectiveness

- Price vs. Performance: Consider the overall cost of the ribbons in relation to their performance. While resin ribbons are more expensive, they may be necessary for high-durability applications.

Applications of Thermal Transfer Printer Ribbons

- Retail and Logistics

- Barcode Labels: Used for labeling products and inventory, ensuring efficient tracking and management.

- Price Tags: Durable and legible tags for various retail products.

- Manufacturing

- Product Labels: Labels that withstand harsh conditions such as chemicals and high temperatures.

- Safety Labels: Important for identifying hazardous materials and ensuring safety compliance.

- Healthcare

- Patient Labels: Labels used for patient identification, requiring high durability and clarity.

- Specimen Labels: Essential for tracking and managing medical samples.

- Electronics

- Component Labels: Used for labeling electronic components and parts, often requiring high precision and durability.

Choosing the Right Ribbon for Your Needs

Selecting the right thermal transfer ribbon depends on various factors including the type of material you’re printing on, the conditions the labels will face, and your budget. Here are some tips for choosing the right ribbon:

- Assess Your Needs: Determine the type of labels you need and the environment they will be used in.

- Consult with Experts: If you’re unsure which ribbon to choose, consult with a labeling expert or supplier for recommendations.

- Test Samples: Consider testing samples of different ribbons to evaluate their performance before making a bulk purchase.

Conclusion

Thermal transfer printer ribbons play a crucial role in ensuring high-quality, durable prints. By understanding the different types of ribbons available and their respective advantages, you can make informed choices that meet your specific printing needs. Whether you’re printing barcodes, product labels, or safety tags, choosing the right ribbon ensures that your labels perform well and last long.

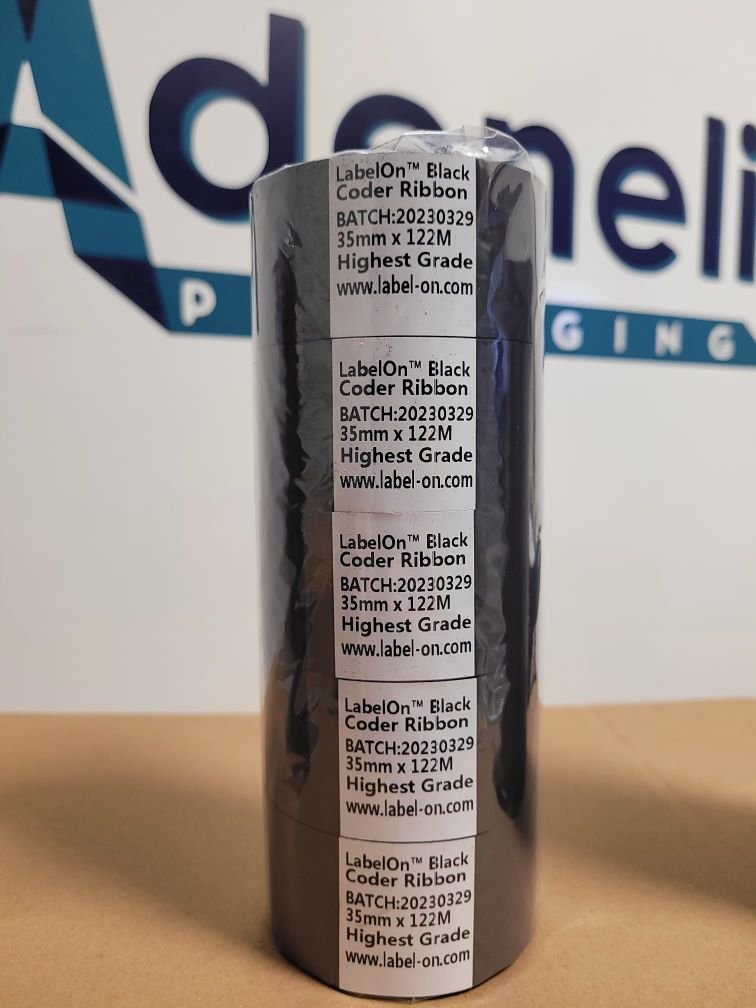

For more information on thermal transfer ribbons or to explore our range of products, visit our LabelOn Thermal Transfer Ribbons page or contact our team for expert advice.