Confidence is built up from experience. This is true no matter what field you may find yourself in. But although one must start from the ground up, when it comes to the importance of your business, it is imperative that you know the very basics in order to provide the best possible service for your clients. When your customers approach you, it is because they have trust in your product. As such, giving your clients advice must never be dealt with a hit-or-miss attitude. This article will guide you into the process of how to confidently and accurately provide to your clients the proper information they will need about product labeling samples.

Product Labeling Automation: A Step Up from Manual Labeling

Once your client’s company decides to move away from hand-labeling towards semi-automated or fully-automated product labeling, they are entering a new level of production with new constraints. There are significant differences among these three, not least of which is the amount of control the operator has on the production line.

When hand-labeling, the operators have a chance to make corrections for product, packaging, and label variations. They have the advantage of tactile dexterity and vision. With semi- or fully-automated product labeling, the product container itself must be oriented properly and detected by the labeling machine at the appropriate level. It must then be labeled perfectly by the product labeling machine.

An exaggerated example of this can be found in our video discussion of “Taking On This Cookie”.

Disclaimer: This is a case study for discussion purposes only. No claim is made as to the supply of equipment or the endorsement by any of the parties or products contained or seen in this video”

With Automated labeling, we need to orientate the product, detect the product and wipe or wrap a label onto the moving surface of the product.

Sources of Variations in Production

This segment of the article discusses the common sources of variations in clients’ products. It is necessary for them to understand these important distinctions as there is no one-size-fits-all solution for product labeling. It is more often than not, customized to the specific needs of each client’s business. Having a thorough grasp of this information is needed so both you and your client can reach a good understanding of how to proceed.

- Product size – Variations in product size are inevitable even for plastic or glass containers. A simple example of this is a product that is approximately 200mm tall. Even though these products are made with this specification, multiple of these products can easily have a height variation of 0.5% or 1mm variation. This information is important to know as these small changes may impact the accuracy of label application.

- Product shape – Unique product shapes are great for the consumers’ eyes but they may present the most complex kind of variation for automated product labeling and indeed, for hand labeling.

Labeling with self-adhesive labels requires that the label is applied to a surface that is either flat or has a curve in only one direction. With round bottles, the curve is in the direction of the circumference. In some instances, the manufacturers of round containers do not carefully control the shape of their containers and you see variations in the walls of the round bottles which results in complex contours (A surface with a curve in more than one direction).

Explaining to the client variations in product shape can enlighten them on the complexities of labeling these products.

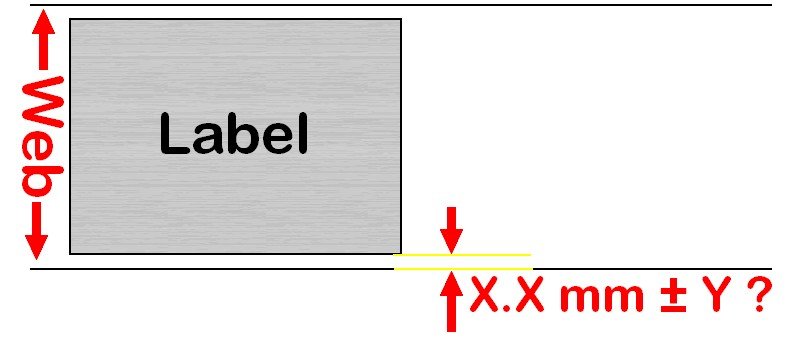

- Label Variation – While the die shape of a label may be fixed and invariable, its position on the web will vary:

The label manufacturer should be able to advise of the slitting tolerance of the web they can achieve; this can often be +/- 0.5 or 1.0 mm. These slitting tolerances lead to label position tolerance as the label head that dispenses the labels is fixed in position.

While the shape of the label itself is fixed and invariable, its position on the roll (and those subtle differences in the web), can have an impact on the accuracy of label application. It is important to explain to the client the label position tolerance they will need to take into account, as the label head of the product labeling machine is fixed in position as it dispenses its labels.

- Operator Setting Variation – A skillful operator is an invaluable part of any team, however, they are still human, and so, may occasionally not set the machine in its optimum setting.One difficulty the operator faces is knowing if his/her setting is based on the perfect bottle and label. They determine this with the use of a bell curve of variation/tolerance. If the operator sets the machine based on samples that are not at the center of their bell curve of variation, then the labeling results will be off slightly and end up inaccurately positioned.

- Machine Variation – Product Labeling machine variations come from a few different sources. While many variations in machine label placement can be attributed to the setup, other discrepancies may be due to the machine’s capabilities on label tracking, product sense, label gap sensing, label speed, and product label surface speed mismatch.

With Round and Flat Bottles, the LabelOn™ variation in label placement will be within +/- 1.0mm usually much better.

With Oval Bottles, the LabelOn™ variation in label placement width-wise will be within +/- 1.5mm usually much better , height variation remains within +/- 1.0mm usually much better.

3.0 Assessing Samples

Sample Assessment: Why Do We Need Product Samples from Our Clients?

Evaluating your client’s products is an important step that both parties must be active in. The initial evaluation phase includes the client’s description of the products, generally with accompanying photos or videos of said products.

Understanding the container and its contents, the current processes involved with their processing and sealing, and issues that may arise in transport or handling are discussed thoroughly so you understand how to go about providing accurate information on the next step of the process.

Tolerances, i.e. the allotted amount of deviation for a product’s specifications that are still allowed to meet its standards of quality, are also discussed in this stage. In cases of labels and packaging, these tolerances are usually available from their respective manufacturers. It is important to discuss this because there are many instances where we encounter people cutting costs or opting for cheaper packaging suppliers where these tolerances are not available. Once these topics are understood and honored, then the transaction is generally expected to be successful.

standards of quality, are also discussed in this stage. In cases of labels and packaging, these tolerances are usually available from their respective manufacturers. It is important to discuss this because there are many instances where we encounter people cutting costs or opting for cheaper packaging suppliers where these tolerances are not available. Once these topics are understood and honored, then the transaction is generally expected to be successful.

Our label partners need to thoroughly understand the source of the tolerances and insure

THE SIZE OF THE LABEL DOES NOT EXCEED THE DEFINED LABEL PANEL LESS THE SUM OF ALL TOLERANCES; see examples below:

3.1 Example Round Bottle Label Height:

- A round bottle with a total height of 100mm diameter 25mm and label panel height of 75mm needs labeling

- The manufacturer of the bottles states a height variation +/- 1% = +/- 1mm

- The label Manufacturer states a slitting tolerance +/- 1mm

- Operator skill allowance of +/- 0.5mm

- Labeling Machine tolerance is +/- 1mm

- Total tolerance is +/- 3.5mm

- Therefore maximum label height should be 75mm less 7mm = 68mm

3.2 Example Flat Bottle

- A flat Bottle with a total height of 150mm, Width of 80mm, Depth of 40mm has a label panel height 80mm and width 75mm needs labeling.

- The manufacturer of the bottles states a height and width variation +/- 1% = +/- 1.5 mm height and +/- 0.8mm width.

- The label Manufacturer states a slitting tolerance +/- 1mm (this affects height placement only)

- Operator skill allowance of +/- 0.5mm (this affects both height and width placement)

- Product Labeling Machine tolerance is +/- 1mm(this affects both height and width placement)

- Total tolerance is Height +/- 4.0mm , Width +/- 2.3mm

- Therefore maximum label size should be Height 80mm less 8.0mm = 72mm, Width 75mm less 4.6mm = 70.4 mm

Exaggerated Diagram to quickly conceptualize:

3.3 Example Oval Bottle

- An Oval Bottle with a total height 150mm, Width 80mm, Depth 40mm has a label panel height of 80mm and a width of 75mm needs labeling

- The manufacturer of the bottles states a height and width variation +/- 1% = +/- 1.5 mm height and +/- 0.8mm width

- The label Manufacturer states a slitting tolerance +/- 1mm (this affects height placement only)

- Operator skill allowance of +/- 0.5mm (this affects both height and width placement)

- Labeling Machine tolerance is +/- 1.5mm in the width direction and +/- 1.0mm in the height direction

Total tolerance is Height +/- 4.0mm , Width +/- 2.8mm - Therefore maximum label size should be Height 80mm less 8.0mm = 72mm, Width 75mm less 5.6mm = 69.4 mm

4.0 Samples Stages

Other important reasons why samples are needed is to determine the following:

- Recessed label panels are not easily seen on photo or video

- Round bottles wherein the label panel have a smaller diameter than other areas of the bottle or its cap

- Tapered round bottles

We later need larger quantities of samples and Labels for testing the machinery so the client knows what to expect prior to shipment and so the client can approve a machine prior to its shipment.

Eventually, after an agreement has been made, additional samples and labels may be requested for machinery testing and to illustrate to the client what to expect once their machine arrives.

Once the transaction is completed and the machine is sent out, ongoing communication between you and your client is necessary to address any issues which may arise. Good customer service is always a plus in any kind of business. Nourishing this connection will then become a long-term investment for both parties, ensuring good business for both sides for years to come.