It’s been a long process, refining your product. And after much consideration, you’ve settled on using bottles to present your product to the world. And since you understand the importance of good packaging, you find yourself in the market for labeling machine for bottles. But where do you start?

Labelling Machine for Bottles

Not all labeling machines are made equal. With the hundreds of types out there, it is important to understand what it is that you need for your business. You’re going to need a bottle labeling machine that can keep up with your current production speed, if not actually make it faster. You expect this machine to allow your process to run smoothly and of course, you’re going to want something that can apply labels efficiently and accurately each time. This is where LabelOn™ Labeling Machine for Bottles comes in. With our extensive lineup of label machines for bottles, we are certain to have exactly what you need.

There is a multitude of labeling machine types out there. And it can be a daunting task to figure out which one you’ll need. Depending on the configuration you want your label to be applied, there are a few types of placement.

- Horizontal Wrap Labels allow you to wrap around the entire bottle. It is the conventional type most people see and are good for bottles with rounded bottoms. These are typically seen in cosmetics and even the food industry.

- Vertical Wrap Labels are usually for bottle designs that are more angular (i.e., square or rectangular), and are also seen in cosmetics and in pharmaceuticals.

- Front or Back Labels are used with different types of bottle designs. They are placed on more than one side of the bottle and can be configured depending on your machine and setup.

- Top and Bottom Labeling is suitable for various flat products such as plastic boxes, lids, and caps, bags, cartons, etc.

After considering the type of labels you want to go for, understanding the types of label machines for bottles that you’ll need may also depend on other factors such as how many labels you need to apply per week or even the level of automation you want in your machine. At LabelOn™ we have a wide range of labeling machines to cater to your needs, ready to adapt to your ever-growing business.

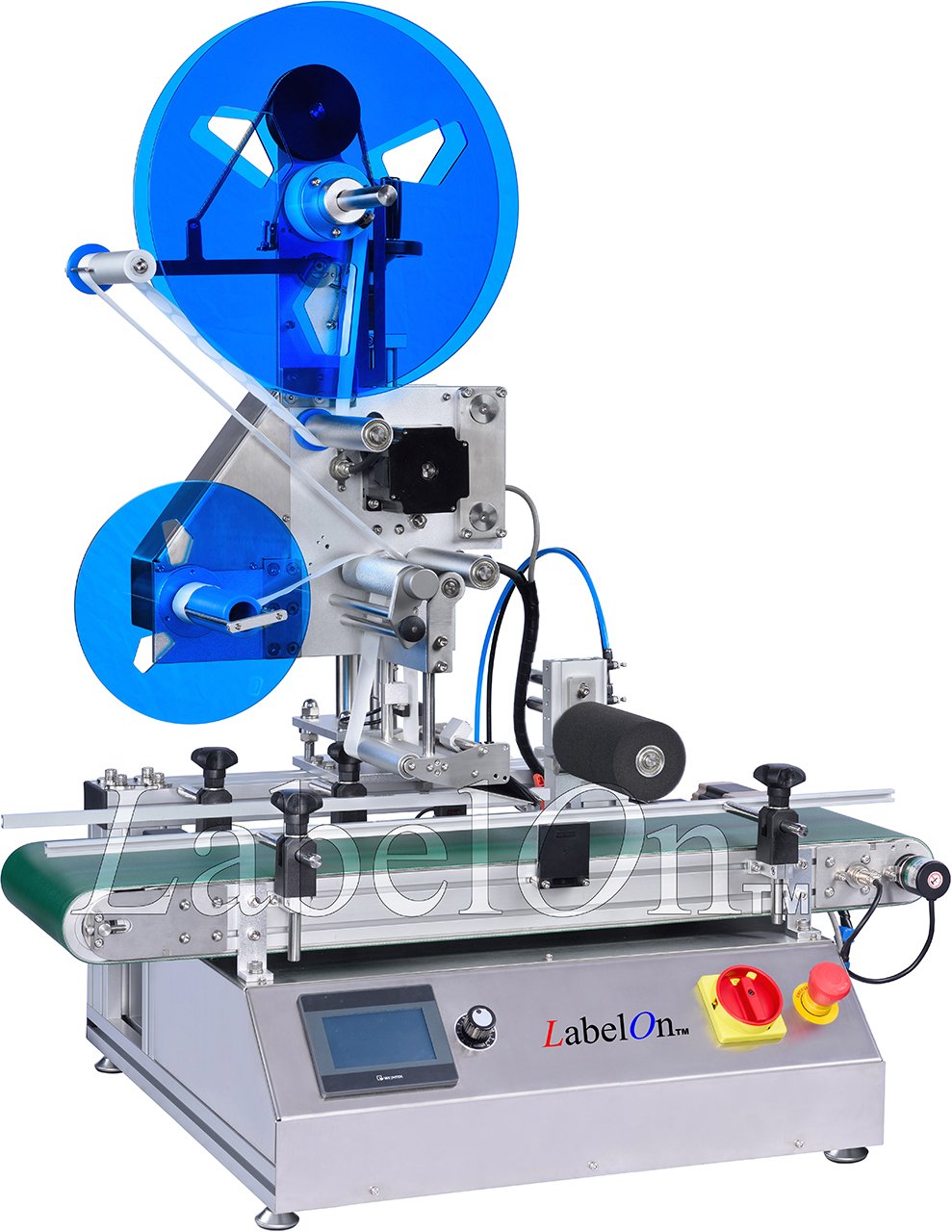

Automated Standalone Top Labeler with a Mini Footprint

Suitable for various flat products such as plastic boxes, lids, and caps, bags, cartons, etc. Suitable for integration with other production line equipment including our SealerOn™ Mini Induction Machines to increase production output on the space of a large desk.

Labeling Machine Features:

- Color Touch Screen

- Memory to store up to 120 different Jobs

- Digital Position Indicators on Label Head Position Adjustments

- Intuitive Controls

- Speed Synchronization

- Digital Speed Encoding

- Auto Set Function (Label Length and Label Stop Position)

- Optional two Step Label Release for leading edge Label Tamper evidence

- Adjustable Label Placement

- Labeling accuracy ±1.0mm (±¹/₁₆ inch)

Labeler Machine Specifications:

- Nominal Footprint size (L) 870mm

(34 ¼ “) (W) 970mm (38 ¼ “) (H) 1090mm (43 “)

- Product Height of 2.5mm (0.1 “) to 100mm (4.0) ” tall (Standard)

- Product Width 12.5mm (½ “) to 150mm (6 “) (Standard)

- 12 mm (½ inch) to almost 150 mm (5.9 inches) tall; Please note the Backing for the label should be between 1.0” to 6.0″

- Label Length of 15mm (⁹/₁₆”) to 380mm (15 “)

- Labeling accuracy +/- 1.0mm (¹/₁₆ “)

- Label Roll Core 76mm (3 “) (inner diameter)

- Label Roll Capacity 380mm (15 “) (outer diameter) That’s Huge!!

- Power Single Phase 110v 60Hz or 220/240V 50Hz – 800W

- Stepper Motor driven Label Head

- ASUS#304 stainless steel and anodized aluminum construction

Label Applicator Available Accessories :

- Hot Foil Coder for in-line Date or Batch codes

- Transparent label sensor for clear labels

- Taller Label Head

- Wider Conveyor

- Pneumatic Tamp (For tamper evidence labeling)

- Hang Tabs Application Conversion Kit